The Original NET™

Based on extensive research and field experience in addressing petroleum and chemical spills, EIC has developed a simple yet practical solution to remediate both light and dense non aqueous phase liquids (LNAPL and DNAPL), also known as free phase product from subsurface plumes. The solution resulted in the development of a unique tool known as Non-aqueous Extraction Tool (NET™). The NET™ recovers primarily the NAPL - eliminating pumping of contaminated groundwater (typically produced with conventional remedial techniques) that would increase lifecycle costs and perpetually extend the time to reach remedial end points.

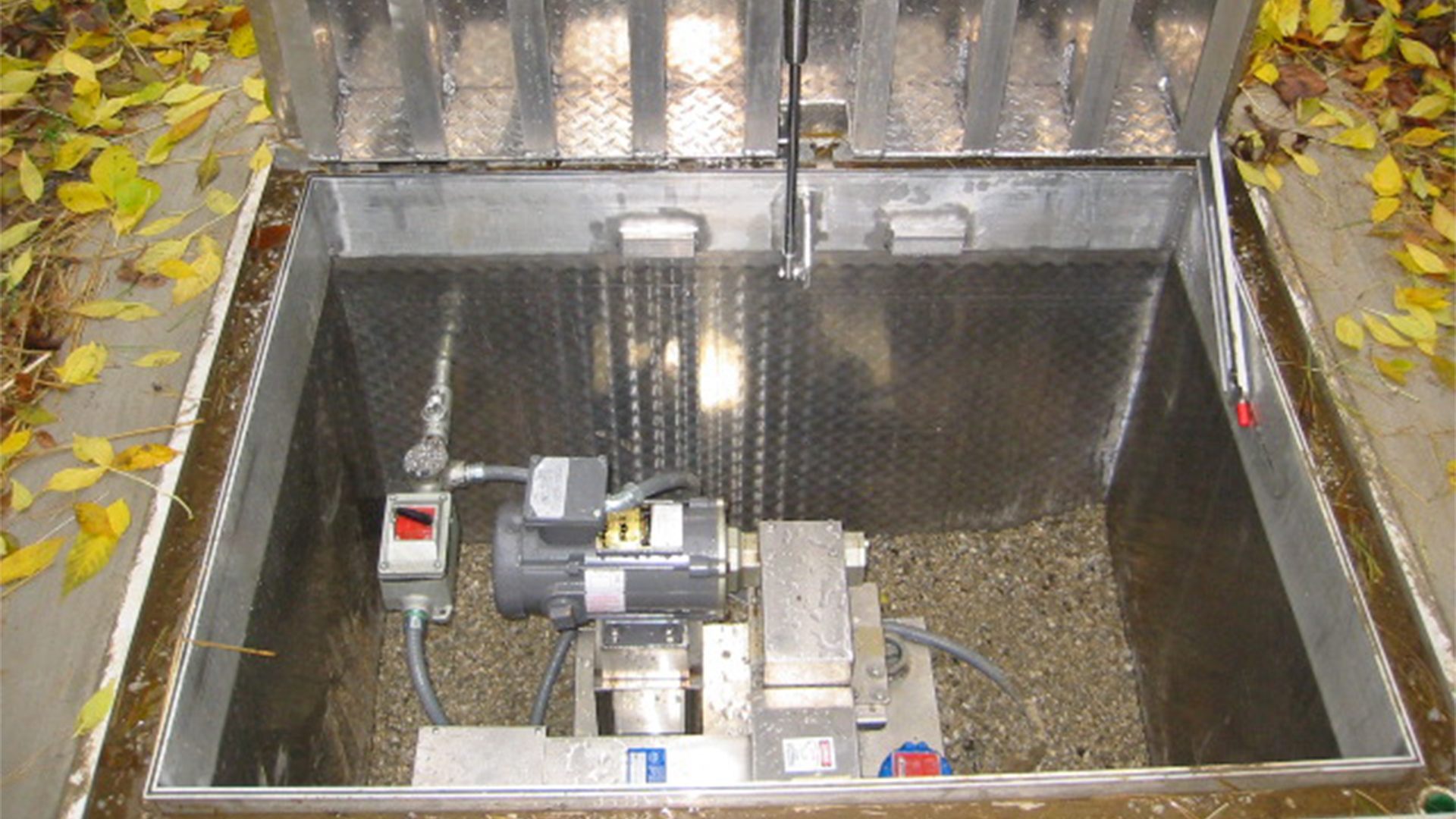

The NET™ utilizes oleophilic/hydrophobic bristles/fabric (NAPL fabric) to absorb NAPL with a 99% recovery efficiency. The fabric rotates in a continuous loop into the well intercepting the oil-water interface. As the fabric travels through the interface, NAPL is adsorbed. AT the top of the well, the fabric wrings through a set of squeeze rollers housed in a specially designed desorption unit. The desorbed NAPL from the wringer is gravity drained into a storage drum or tank. If NAPL continues to recharge in the well, the variable speed drive on the NET™ can be used to match recovery to recharge in an infinite range of water table fluctuations.

The NET™ approach, therefore, eliminates perpetual liabilities. As an added value, the NET™ systems utilize less than 100 watts of energy and produce negligible green house gases. The recovered product is typically recycled - thus eliminating disposal costs. The end result is the elimination of perpetual remedial programs at substantially reduced life cycle costs.

NET™ is both an Evaluation & Remedial Tool

The Original NET™ is protected with a registered trademark

The NET™ tool is not only a remedial tool but also serves as an evaluation tool - first to determine the optimal NAPL recovery potential. The resulting data can be used to demonstrate technical impractibility if NAPL recharge is dismal. This important attribute to serve in a dual role is unmatched by conventional technologies that often lead to unnecessary may not provide optimal recovery rates or become ineffective as the source material depletes.

Unlike bail down tests impacted by water recovery and Darcy-based assumptions, NET™ can be used to:

- Assess true NAPL recharge rates using Empirical Data

- Define optimum NAPL recovery rates to match recharge

- Demonstrate Technical Practicability (TI) if NAPL recharge is found to be dismal

- Avoid unnecessary and costly remedial system installations

In striking contrast with conventional remedial systems that mostly produce contaminated water or air, the NET™ is the most efficient tool to recover NAPL at the most optimal recovery efficiency. As a remedial tool, the NET™:

- can match NAPL recovery to recharge rates (with the variable speed drive) - as the source zone depletes

- adapts to an infinite range of water table fluctuations

- recovers NAPL at 1- 240 gallons (900 liters) per day

- footprint is as low as 4 x 6 feet (1.2 x 1.8 meters)

- can be installed in wells as small as 2-inches (50 mm) in diameter up to a depth of 400 feet (120 meters)

- can significantly reduce the life-cycle costs